Customized solutions for insulation issues within the process industry

Providing total solutions for insulation issues within the process industry is the strength of ISOPARTNER Netherlands. In the production process of this industry, ingredients are processed chemically, biologically or physically to arrive at an end product.

The industry can be divided into chemical, electronics, pharmaceutical or metal industry and therefore requires customized solutions. Our expertise in insulation materials translates this into a suitable solution. As the process industry is the most energy consuming sector, CO2 reduction also plays a very important role in this sector.

We have an insulation range that can be used from -200°C to +1600°C.

Chemical plants

Moisture accelerates pipe corrosion and increases the heat load of a cooling system. As a result, the system loses enormous power and the pipes are damaged. This can be prevented by choosing the right materials. A fluctuation in the temperature in pipes can worsen the efficiency of a process. Good insulation can very quickly save costs and reduce the burden on the environment.

Pharmaceutical companies

The pharmaceutical industry produces drugs. This is done in factories where high demands are placed on machinery and the manufacturing process. Quality and safety are top priorities here. To ensure the accuracy of the processes, temperature is also very important and thus the use of the right isolation solutions. Drug ingredients are measured and weighed very accurately to ensure the right amount of them in the drug. The weighing and production of drugs is done in cleamrooms. ISOPARTNER has developed special sound-absorbing products for these rooms.

Petrochemical plants

Industrial plants for the extraction and processing of oil and gas have a great need for reliable technical insulation. The size and complexity of petrochemical plants place extremely high demands on material quality, insulation performance and durability of the insulation materials used.

Food and beverage industry

During food production and processing, care must be taken to ensure that no harmful substances or particles enter the food. Harmful particles include dust, fibers, bacteria and volatile organic compounds. In addition, all surfaces must be easy to clean in areas where food or thinking is produced. This applies to insulated pipes or equipment as well as acoustic solutions needed to reduce noise.

Whereas thermal insulation is often provided with stainless steel finishes, this is not always possible for acoustic products. ISOPARTNER has a wide range of solutions for hygienic areas. Among other things, these solutions offer excellent protection against mold and bacterial growth.

The optimal total solution

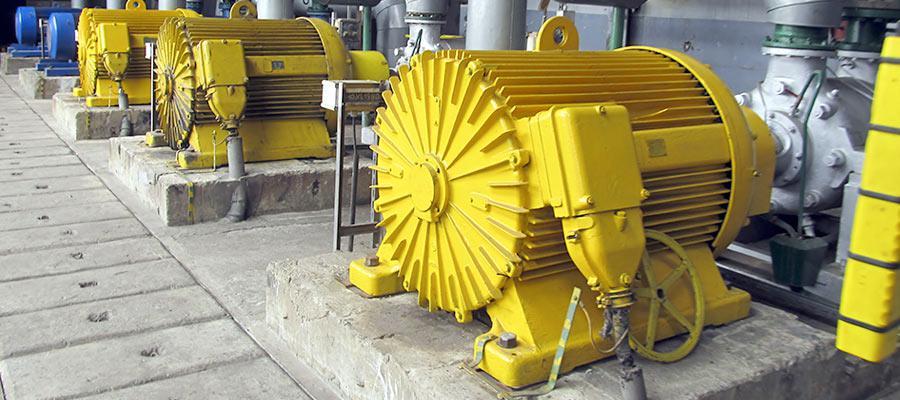

People in industrial working environments are exposed to numerous noise sources such as machines, generators, pumps, pipes, conveyor belts,... ISOPARTNER Nederland provides optimal total solutions -both standardized and customized- that both minimize noise pollution on site, but also greatly reduce the nuisance to the environment.

Prefabricated bends and other custom products

In addition to fire resistance, energy conservation is also an extremely hot topic. ISOPARTNER Nederland supplies insulation materials from renowned suppliers and partners, but also produces customized products, such as prefabricated bends. Since prefab elbows connect perfectly to pipes, unnecessary heat loss is prevented and the time required for installing insulation is greatly reduced.

Industrial insulation

Industrial pipelines and district heating pipes that transport liquids and gases, as well as industrial installations such as containers, tanks, exhaust pipes, boilers and dryers, require effective insulation. To ensure process functionality, heat losses must be reduced and protection against combustion on contact must be ensured.