Solutions for the OEM sector

OEM is a broad term. It includes manufacturers of, for example, generators, pumps, compressors, transformers, elevators to mail sorting systems. Mechanical engineering is also often grouped under OEM, but for this we have specific page.

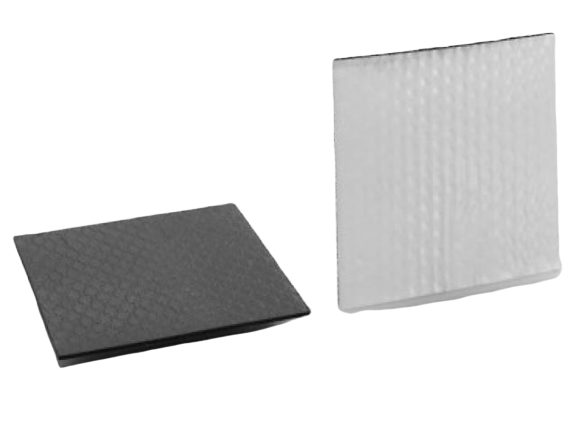

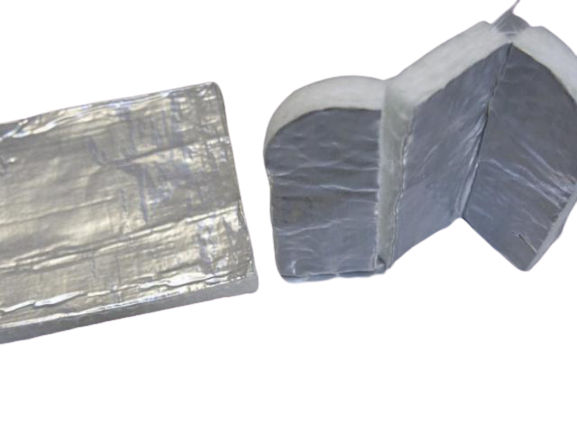

For the OEM sector we have a large range of thermal, acoustic and fire protection products, in addition we offer solutions for sealing, protection and filtration. Especially sealing is a very important factor in acoustic and thermal problems, which is sometimes forgotten. By using or combining materials in the right way, we find the perfect solution. Many basic products we have in stock, but almost always we supply custom parts for application at OEM customers.

Processes at our OEM customers

Our consultants have knowledge not only of our solutions, but also of customers' production processes. Many players forget that many costs can be reduced there. Also working with FMEAs for risk analysis and achieving the strictest requirements in our production is daily practice. Our experience as a 1st tier supplier for OEM customers and our quality systems ensure that you get products of perfect quality.

We also contribute to the logistics process and relieve our customers of their worries through just-in-time delivery or stock management. As part of the Ipcom group, one of the largest players in the field of insulation products in Europe, Isopartner also has the financial resources to work with large OEM parties.

Insulation systems for product manufacturers

Devices and products emit sound and often have thermal or fire challenges. That's just the way it is. Where thermal properties and fire resistance affect energy consumption or safety, sound has a significant impact on how we experience products. Are you a manufacturer developing devices or products? And do you have a challenge in the thermal, fire resistance or acoustic field?

Then you might be interested in contacting us. Did you know that acoustic insulation in many cases also has thermal properties and that this also applies the other way around? ISOPARTNER is one of the few companies that can combine these areas of expertise. And it doesn't stop there.

Specific thermal and acoustic solutions

Sometimes a product does not have to make a noise to still cause noise pollution. Consider all metal products. A glass container in itself does not make noise, but throwing in bottles still causes a nuisance. A metal sink or bathtub also makes no sound, but running water into it can still cause a nuisance. Similarly, a water hammer or aluminum window sill do not cause a noise....until it rains. A furnace should be kept at the right temperature with as little energy as possible. ISOPARTNER also offers thermal, acoustic and fire-resistant solutions for these products and many others.

Making a product quieter, more efficient or safer? ISOPARTNER thinks along with you.

A good solution starts with listening. In consultation, we carefully map out your requirements and wishes. Where necessary, we take measurements, make calculations with our calculation programs and produce prototypes to validate calculations. We have a practical and pragmatic attitude and also keep an eye on other aspects, such as producibility and your processes. In this way we develop the best solution together. This solution also depends on your situation. Are you looking for a quick fix for an existing product or are you still in the early stages of development? What is the series size of the product? Many starting points influence the process we go through with you.